Spar Varnish Wrap Finish

A note about this page.

It has been problematic for me because of the size and quantity of its images. It displays best

at a width a little beyond the point where the bottom scroll bar of your browser disappears at about

850 pixels. It is best viewed with Firefox.

I use a Mac and no longer have access to Explorer. Some have told me it does not display properly with Explorer.

Rod builder's epoxy, both glue and finish, are known sensitizers. Prolonged exposure either with direct contact with the skin or respiratory exposure to its fumes can lead to a general allergy to the stuff. I have used epoxy for more than 25 years, and my body can no longer tolerate it. There are lots of high strength glues that are very adequate substitutes for epoxy glue, but epoxy rod finish is hard to equal with traditional finishes.

The long standing finish of choice of cane rod builders, from the beginning and to the present, is spar varnish. You won't find the product cane builders use at your local hardware store, but it is available from various marine finish suppliers. I grappled with the decision to either give up rod building or try what the cane guys have always used. It has been a struggle, but I have finally nailed down a couple brands of spar that work just wonderfully for me, giving me the quality I have come to expect with epoxy. The images on this page will give you an idea of what to expect in a Performance Graphite Fly Rod by Dave Lewis from this year on till I finally am put into the ground.

The varnishing process takes about three days for application and about two to three weeks for curing. I usually end up with about five coats, applied close enough together so I don't need any sanding for adhesion. You will notice the barrel shape, due to the centrifugal force exerted on the finish during drying so common with epoxy because of the extremely slow setting up period, is no longer a factor with varnish. The wraps on my current rods will always be a little flatter and perhaps just a little heavier toward the ends than with epoxy.

Durability, given the long standing base of cane rods dating back a hundred years previous to modern synthetic finishes and glues, is almost guaranteed. Granted the hardness and toughness of epoxy is probably not totally achievable with varnish, but the enduring gloss with varnish is definitely much longer lasting than with epoxy. Probably the only fault I have had with epoxy is its dulling and yellowing when exposed to the kind of abuse a fishing rod really can't avoid. Varnish quite simply holds its gloss better than epoxy does.

I've taken on a pretty good range of rods with my new varnish finish now. Just this week I sent the rod below to a customer in England. This is a big 12 wt. with a big fighting butt that isn't shown. The large guides made special problems for my varnish technique. I decided to use a double layer thread wrap too for added strength, which made for a little fatter wrap and rougher surface to cover smoothly.

You can see with the closeup below that smoothness is a given if you have a good hand, a good clean application area, and a good quality varnish. I'm counting on the durability with varnish equaling that of epoxy. The gloss and over all beauty surely is up to my usual standards.

I recently did another rod for Dan, a friend and customer in Salt Lake City. He likes conservative combinations and requested a nice brown thread to complement the deep reddish brown color of the blank. I think it is a good combination. The smoothness and gloss of my varnish work is obvious in this shot.

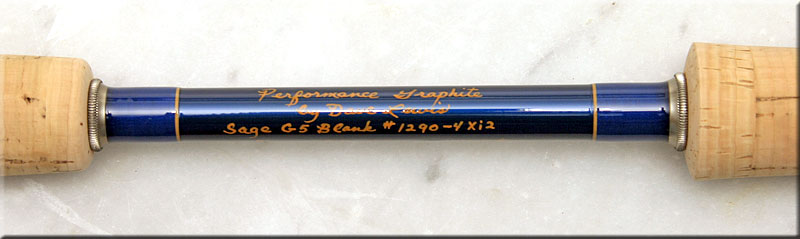

I'm toying with a new series of affordable rods on deep blue blanks that work extremely well with a deep dun blue thread wrap. On the left is an extreme close up of the three ferrule reinforcing wraps. You can see that with a persistent and careful hand, spar varnish is capable of extremely smooth uniform results.

Colors with varnish are just different than they are with epoxy. Since varnish is an oil base, it tends to penetrate wrapping thread a little more thoroughly than epoxy does. The result is a much more translucent look, allowing the base color of the blank to have a greater effect on the overall look of the guide wrap. I'm finding light colored threads on dark blanks produce muted and disappointing results. Thread colors need to be closer to blank colors expecially with deep brown, green, blue, and gray blanks. You will notice a quite different color quality with the wraps on the light glass blank rods shown here. Even the Sage TXL and SLT blank rods, which are a rather light golden color, produce a different depth and color trueness.

The rod shown here has medium brown thread with a dark brown blank. It is easy to see how the dark blank color influences the wrap color, in this case allowing it to almost completely disappear, but for the golden trim at the ends. The trim is a thread that does not absorb finish in the conventional way and maintains its color no matter what you coat it with. Again, you can see the overall smoothness and gloss of the varnish and the even parallel build of the wrap. I think it is quite attractive and surely a little lighter weight than the thick epoxy the major rod companies glob on their rods.

New this year from Sage is the VT2 series of rods replacing the VSP and VSP Lite rods from previous years. These rods are surprisingly light and powerful and will be priced very competitively. I have done only three of them so far. The blank is a blue which seems a lighter version of the Xi2 saltwater blanks. Finding a wrap color that works perfectly with the blank color has been a challenge. I think I will settle on something between the two samples here. I did the third rod for a customer in Arizona. I used a medium blue with that rod and think it will probably be my first choice. Unfortunately I didn't photograph it before I sent it along to him.

The inherent tint of the spar varnish I use for the wrap coatings tends to change the wrap colors in comparison to what epoxy has done in the past. It is quite a bit more amber than epoxy and you can see that it changes the light blue wraps of the second VT2 rod to a turquoise, while leaving the dark blue one above just about the same tint as epoxy produces. You might take a close look at the reel seat on the rod above. That is a Bellinger large diameter uplocking screw lock seat. Since Bob Venneri is no longer doing reel seats, I've been forced to seek other sources. I am pleased at the wonderful machining of the Bellinger seats and think they will be a very satisfactory alternative to Bob's seats as my inventory of them runs out. The rod below has a particularly nice maple insert seat from Struble. The model is the U24 and the quality is typical Struble, with wonderful fit and great polish. That rod is a Sage SLT blank rod I just finished for a customer in Australia.

I'm excited about the possibilities spar varnish have opened for me. I think you will share my enthusiasm when you have an opportunity to give my new finish some close scrutiny. Thank you for looking at my work. I hope you will give my rods some careful thought.

The Second Year of My Varnish Work

I have worked hard over the last year to perfect my varnish work. Having gone on Social Security last year, I've scaled back my work to about fifty rods a year now. That is enough to keep me busy and keep my customers reasonably satisfied. I'm a little slower to come along with a new rod, but I don't let anyone down.

One of the problems with my production last year was drying times. The varnish I use dries tack free fairly quickly but is a long time attaining a complete cure. In fact by the end of the summer the rods I carried in my Montana fishing car had cured to a much harder finish than I had thought possible back in the spring when I was still building. In the summer heat of the car they got really good and hard, altogether as hard as the epoxy I had used previously. What I found is that the curing process is a product of both time and heat, with heat speeding the process up a good bit.

The logical solution was to build or buy a drying cabinet. I have a nice corner to make into a corner drying cabinet, but, after considering the construction time and the fact that it would take a corner that I really need for space to move around, I decided to go with a commercial curio cabinet I was able to purchase locally. I put it in a nice nook in my office, where it has become a piece of furniture in addition to serving a vital purpose in the rod building process.

Here you can see the upper half of the case. I have put hooks in the top to hang the rod sections from and a floor in the bottom equipped with four light bulbs and a dimmer control to regulate the heat output. I tried a thermostat, but found it undependable. The dimmer does just fine and makes the light bulbs last just about forever.

It is sad for me to realize that, as I move into my, probably twelfth year of using Bob Venneri's wonderful reel seats, that my tenure with him has drawn to a close. Bob, like many of us has found life too full to be able to continue with a craft that is all too time consuming and not nearly profitable enough. I have found wonderful replacements in Bellinger, REC, and Struble reel seats, but using Bob's seats was a collaboration of years of friendship and cooperation, making my rods the products of two fine craftsmen. Bob knows that when he can return to his craft once again, he will be assured of my continuing loyalty.

Moving into my second year of using varnish as my wrap finish, I have found continued success with two brands of varnish. The first two coats need to be done with a fairly viscous, penetrating, yet tough varnish that will seal the wraps and coat the guide feet to prevent corrosion and loosening. I have chosen to use a high grade polyurethane varnish for those first two coats. I then follow up with three to four coats of a good spar varnish to give the glossy build and lasting sun and weather protection that is every bit the equal of epoxy used by the rest of the industry. As you can see in the pictures, my wraps have a natural, gently rounded, fairly flat, sculptured shape to them, quite different from the fat bulges that have come to be accepted on factory rods. I think the look is at the same time conservative but also traditionally rich and naturally deep. I am pleased with the new look. It is a definite departure from the plastic look of epoxy.

Performance Fly Rods

5798 Singers Glen Rd.

Harrisonburg, VA 22802

540/867-0856

email: MaryLuRods@gmail.com